Nathalie Gamache

Vice-présidente, Marketing et innovation chez Cascades Emballage carton-caisse.

Vice-présidente, Marketing et innovation chez Cascades Emballage carton-caisse.

Aujourd’hui, les arguments en faveur de la protection de l’environnement sont bien connus. Cet objectif commun exige donc que tout le monde contribue à réduire son impact environnemental. En outre, les consommateurs y participent activement et réclament que les petites et les grandes entreprises déploient des efforts écoresponsables majeurs.

Pour les entreprises, il existe plusieurs façons de réduire son empreinte, par exemple, en repensant les emballages. Cela peut sembler compliquer et couteux, mais au contraire, un emballage qui satisfait des critères d’écoconception favorise le rendement d’une entreprise sur le plan opérationnel et financier, sans en compromettre la performance. De plus, en modifiant vos emballages pour des modèles écoconçus, vous tirerez parti de la perception positive que les consommateurs auront de votre marque. Trop beau pour être vrai? Détrompez-vous! Voici des exemples pensés par Cascades pour vous aider à repérer des idées profitables à votre entreprise.

Bonne nouvelle, vous ne partez pas de zéro! Votre entreprise est sans doute déjà partiellement écoresponsable.

Voilà, ce sont tous des exemples de gestes écoresponsables. Maintenant, voyons comment vous pourriez réduire davantage votre empreinte environnementale et en sortir gagnant sur toute la ligne.

Chez Cascades, nous avons développé une grille d’écoconception afin d’optimiser nos designs. La grille est séparée en quatre catégories : la fin de vie responsable, le matériau sélectionné, le design optimisé et la logistique adaptée. Examinons-les de plus près!

Pour commencer, il faut prévoir la fin de vie. Surprenant, mais logique. Donc, pour planifier une fin de vie responsable, il importe de soutenir les trois « R » :

D’ailleurs, saviez-vous qu’il vaut mieux recycler un matériau s’il est à la fois recyclable et compostable? En le recyclant, on évite de devoir produire de la nouvelle matière. C’est le principe de l’économie circulaire.

Bien entendu, le compostage demeure une excellente solution pour disposer des matières qui finiraient autrement au dépotoir.

Au moment d’envisager le bon matériau à utiliser, privilégiez une matière recyclable et recyclée. Heureusement, le carton ondulé de Cascades répond à ces deux critères! En revanche, plusieurs matières sont recyclables, en théorie, mais ne sont pas acceptées dans le bac de recyclage des consommateurs. Par exemple, le Styrofoam (mousse de polystyrène) techniquement se recycle, mais en réalité, une minorité d’endroits le recyclent puisqu’il n’y a pas de marché pour ce produit.

Avec un taux de recyclabilité de 85 %, le carton ondulé est un champion dans sa catégorie, voici quelques exemples innovants dignes de mention.

Un producteur a choisi de remplacer les sacs de plastique habituels par une boîte de carton pour commercialiser ses pommes. Il est gagnant sur toute la ligne, puisque cet emballage protège mieux ses denrées, son produit se démarque sur les rayons et cette solution est plus écologique puisque le carton est recyclé de façon plus efficace que le sac en plastique.

Vous connaissez certainement les paniers de fruits en carton dont l’anse est en plastique. Cette anse n’est pas recyclable. Cascades propose une solution économique et écoresponsable dotée d’une anse solide et pratique en carton. Résultat? Le panier est fabriqué d’une seule matière et se recycle en entier et plus facilement.

Vos emballages sont déjà en carton? Super! Maintenant, sont-ils en carton recyclé ou vierge? En optant pour du carton recyclé, vous diminuez les ressources nécessaires à la production comme les arbres, l’eau et l’énergie.

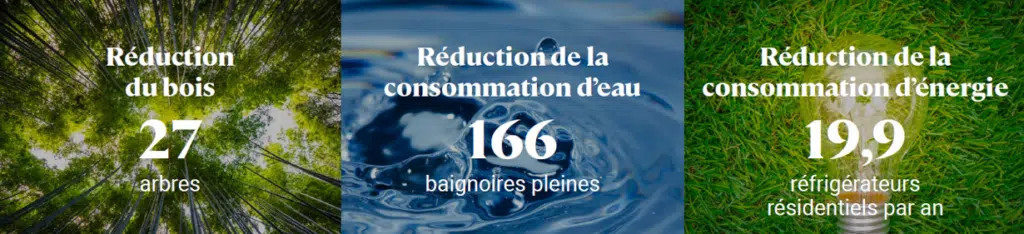

En fait, si on substitue une tonne de carton vierge à du carton recyclé (l’équivalant de 2500 boîtes de déménagement), on sauve 27 arbres, l’équivalent de 166 baignoires remplies d’eau et l’énergie nécessaire pour faire fonctionner 20 réfrigérateurs pendant 1 an. Voilà qui est encourageant!

L’optimisation de la conception des emballages est loin d’être un luxe, c’est astucieux et logique. En repensant toutes les étapes du design, notre équipe cherche à réduire la quantité de matière requise, à éviter le suremballage et à réduire les pertes. Tout cela est synonyme d’économies pour votre entreprise.

Souvent, les boîtes dans lesquelles sont emballés nos produits sont inutilement grandes. Concevoir une boîte sur mesure et au bon format revient à éliminer les pertes d’espace et à éliminer le rembourrage (mousse, papier chiffonné, papier bulle ou sachets d’air). Par conséquent, la quantité de carton diminue, les matériaux de rembourrage sont éliminés et les coûts de livraison baissent puisque chaque boîte prend moins d’espace dans le camion.

Parmi sa gamme de produits pratiques, Cascades propose une boîte à hauteur ajustable. Un choix intéressant pour les détaillants qui souhaitent diminuer le nombre de format de boîte qu’ils utilisent.

Boites pour le commerce en ligne – Cascades

Le maillon faible?

Pour toute entreprise, la chaîne logistique est une étape cruciale, car elle engendre plusieurs dépenses. Pensez au nombre de camions qui participent au transport, aux frais liés à l’entreposage des produits, notamment pour chauffer et éclairer l’entrepôt. Tout cela a un impact environnemental appréciable. En examinant de près chaîne la logistique, il est souvent possible de réduire les ressources nécessaires et, par conséquent, de réduire notre impact. Par de simples modifications, vous avez le potentiel d’apporter des changements positifs et de réduire grandement votre empreinte environnementale. De plus, vous répondez aux exigences de vos consommateurs et aux impératifs d’une entreprise écoresponsable modèle.

Nous l’observons fréquemment : un emballage optimal améliore la chaîne logistique.

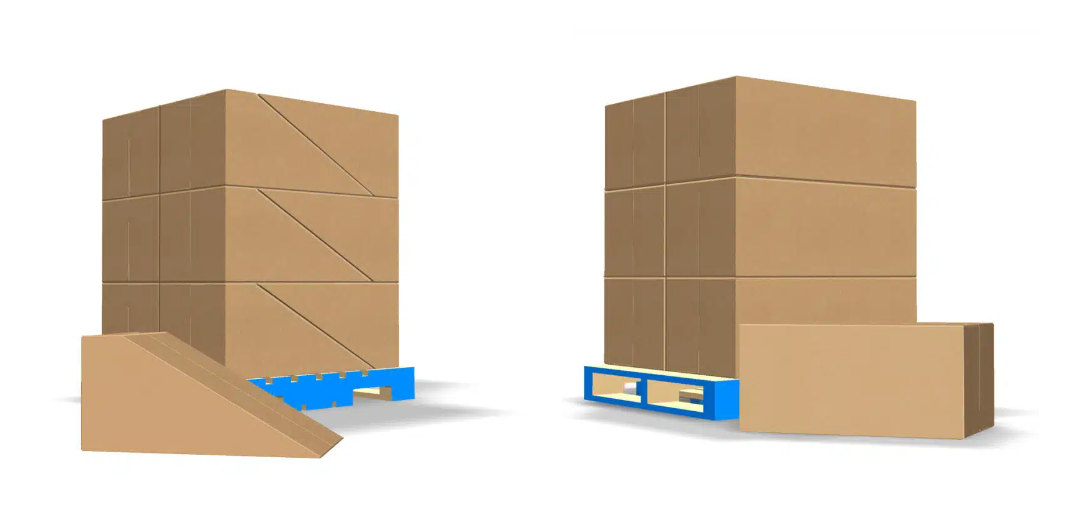

Y avez-vous songé? Réduire le volume des emballages permet d’optimiser la palettisation.

Comme l’illustre l’image ci-dessus, nous avons repensé l’emballage d’un produit asymétrique. Auparavant, le client emballait son produit dans une boîte rectangulaire ordinaire. Par conséquent, la quantité de fibre exigée pour la production de la boîte était plus grande que nécessaire. De plus, il fallait utiliser beaucoup de rembourrage de protection pour combler l’espace inutilisé.

Nous avons donc conçu un emballage qui épouse la forme de l’objet et qui s’imbrique au moment de palettiser.

Constatez les gains :

Ces simples changements ont permis de réduire l’énergie liée à d’entreposage et le carburant nécessaire à la livraison, ce qui diminue les coûts et réduit l’impact environnemental.

En conclusion, nous remarquons que plusieurs entreprises sont sur la bonne voie en matière d’écoresponsabilité. Heureusement, des améliorations sont encore possibles et souvent avantageuses pour vous. En optant pour des emballages écoconçus, vous misez sur un excellent moyen d’atteindre vos objectifs de développement durable.

Comptez sur Cascades comme alliée et fiez-vous à nos spécialistes formés en conception d’emballages optimisés et écoresponsables. Vous n’avez rien à perdre et certainement tout à gagner à examiner une solution d’emballage écoconçu.

Découvrez toutes les solutions d’emballage offertes par Cascades :